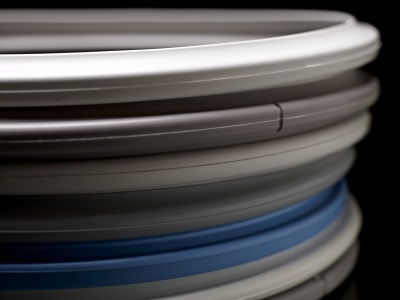

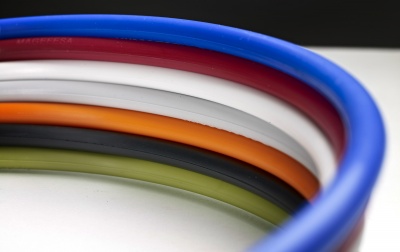

PRESSURE COOKER SILICONE GASKETS AND CORDS

PIONEERS IN THE MANUFACTURE OF SILICONE GASKETS

COECA has been a pioneer using silicone compounds to manufacture pressure cookers' silicone seals.

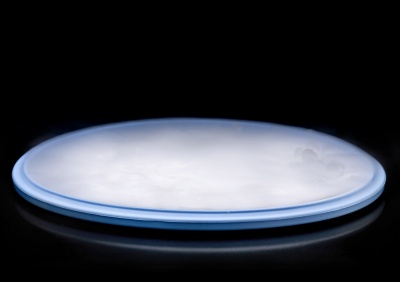

The silicone seal works as the third safety mechanism of a pressure cooker. In case that both safety valves become blocked or do not work correctly, the silicone seal stops the pressure cooker being forced to the extreme which could lead to breakage.

All the silicone compounds we use are FDA-Approved and meet the standard BfR Recommendation XV (Recommendation on Plastics Intended to Come into Contact with Food). These compounds are formulated and manufactured by our company Silicone Technology SITEC, S.A. The possibility to formulate and manufacture our own silicone compounds let us have always-homogeneous materials available according to our top-quality levels.

We have a laboratory dedicated especially to the quality control of our silicone seals. We can get the physicochemical properties of the silicone compounds as well as guarantee a top quality level of the finished product by means of our shooting tests (pressure level to clear steam) and the necessary friction strength to open and close the cooker.

We can set up over 1 cPk levels by means of the use of artificial vision equipment specially designed to the pressure cookers silicone seals' dimensional control.

Select the image you want to enlarge:

Other PRODUCTS IN CONTACT WITH FOOD

SILICONE BUNGS FOR OAK BARRELS

PRESSURE COOKERS SILICONE VALVES

SEALS FOR THE FOOD PROCESSING INDUSTRY